Technical data

Standard Test Method for Rubber Property - Extension Cycling Fatigue

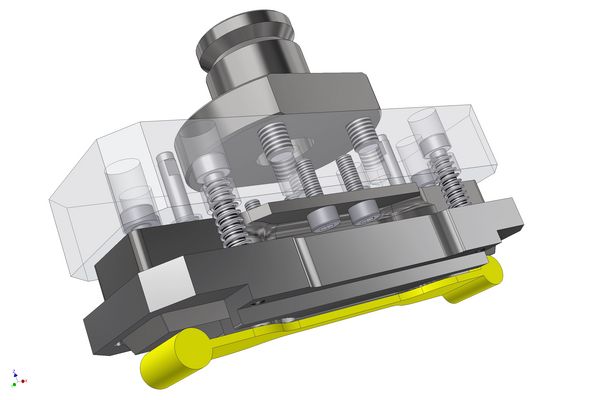

The cutting-die unit „ASTM D4482“ consists of a cutting blade and spring-loaded down holders. The cutting blade is made of powder-metallurgic knife steel and thereby guarantees an extreme lifetime. The blade is transversally sharpened on both sides, which results in vertical cut lines of an exact specimen cross section.

The spring-loaded down holders are matched to the specially shaped specimens.