Technical Data

Tear resistance test according to ASTM D624 B for tear resistance measurements

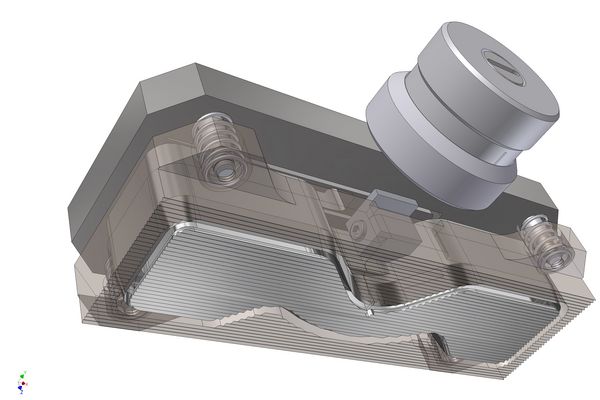

The cutting die-unit „ASTM D624 B“ consists of a cutting blade and spring-loaded down holders. The cutting- & nick-blade is made of powder-metallurgic knife steel and thereby guarantees an extreme lifetime.

Testing the tear resistance requires an exact nick at a defined point on the specimen. We offer a knife without, with fixed or variable scoring depth.

The blades are transversally sharpened on both sides, which results in vertical cut lines of an exact specimen cross section.

Cutting-die geometry

SI-Dimensions of Specimen

Type B of the ASTM D624 standard is an arcuate specimen with an incision (pitch) in the arcuate region. The pitch depth of the nick is 0.5 mm.

The test piece according to DIN ISO 34-1 is identical. Only the cutting depth of the nick (1mm) is defined differently.

Specimen size: 2 x 25 x 110 mm (Nick: 0,5mm)

Characteristics

Available versions of the punching knife:

- punching-knife-unit without nick-knife

- punching-knife-unit with fixed adjusted nick-knife (0.5mm)

- punching-knife-unit with variably adjustable nick-knife (range: 1 mm)

- replaceable nick razor

- Lateral ejector feasible

- Jig adapter for various die-cutter units available

- Blade fully protected